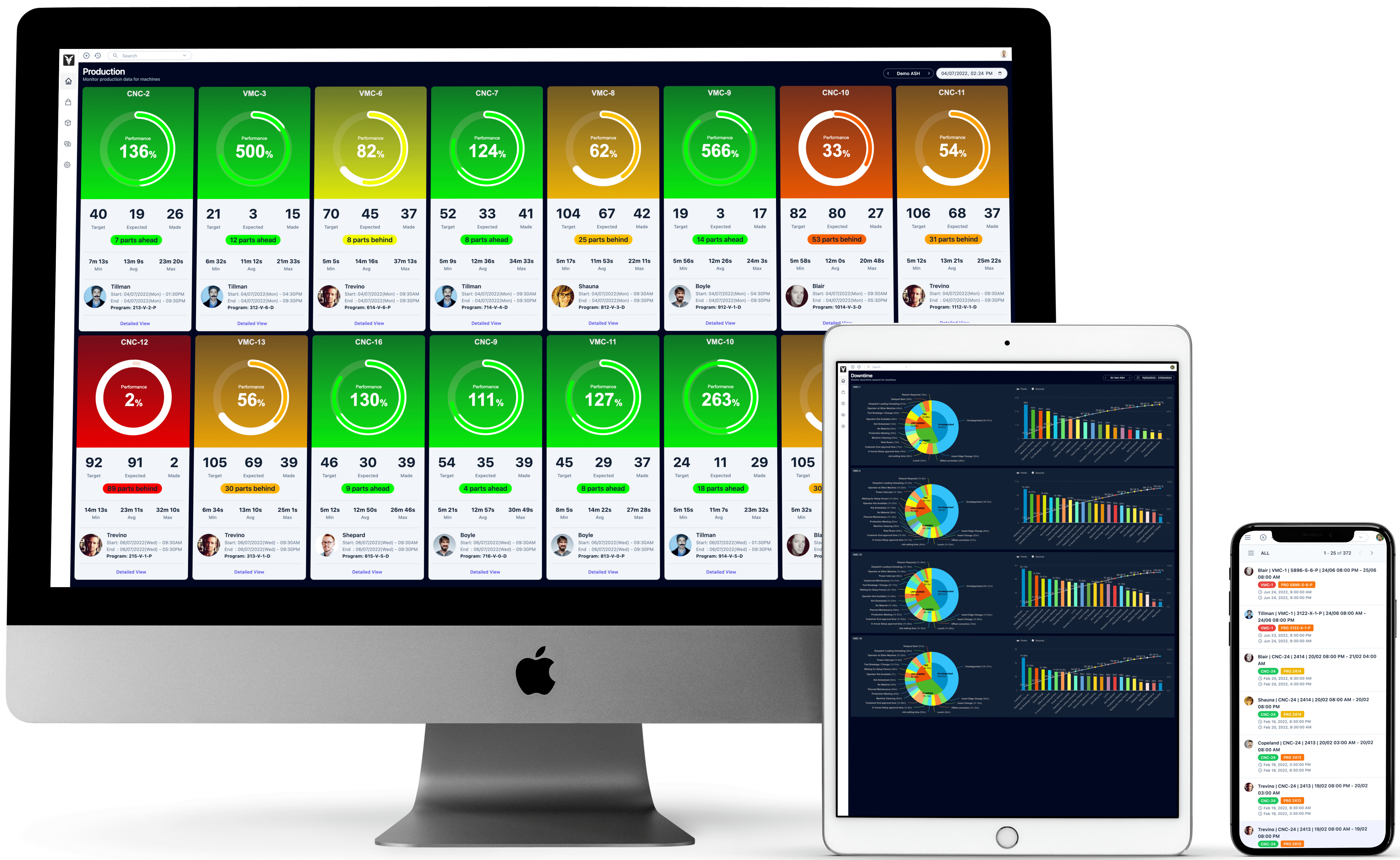

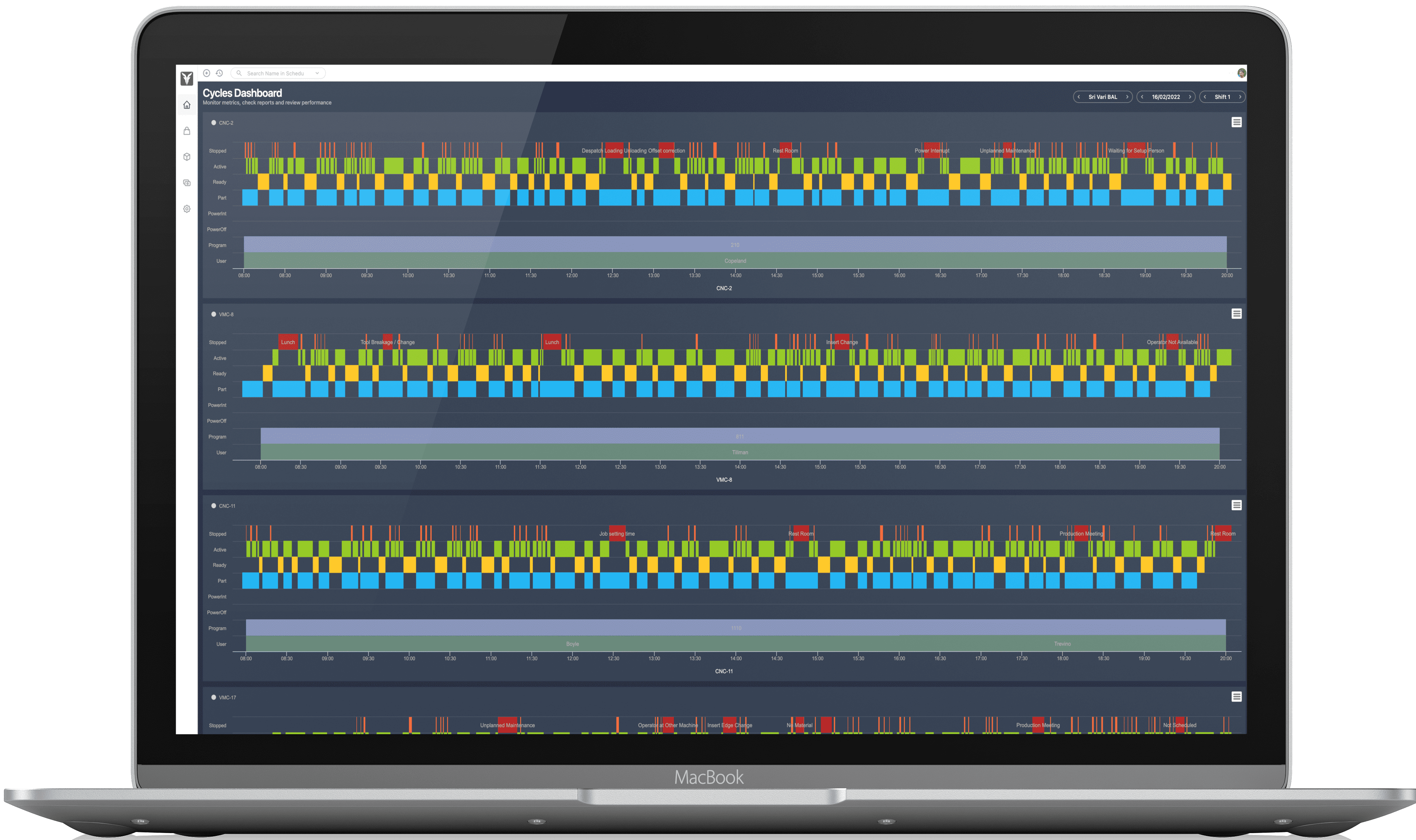

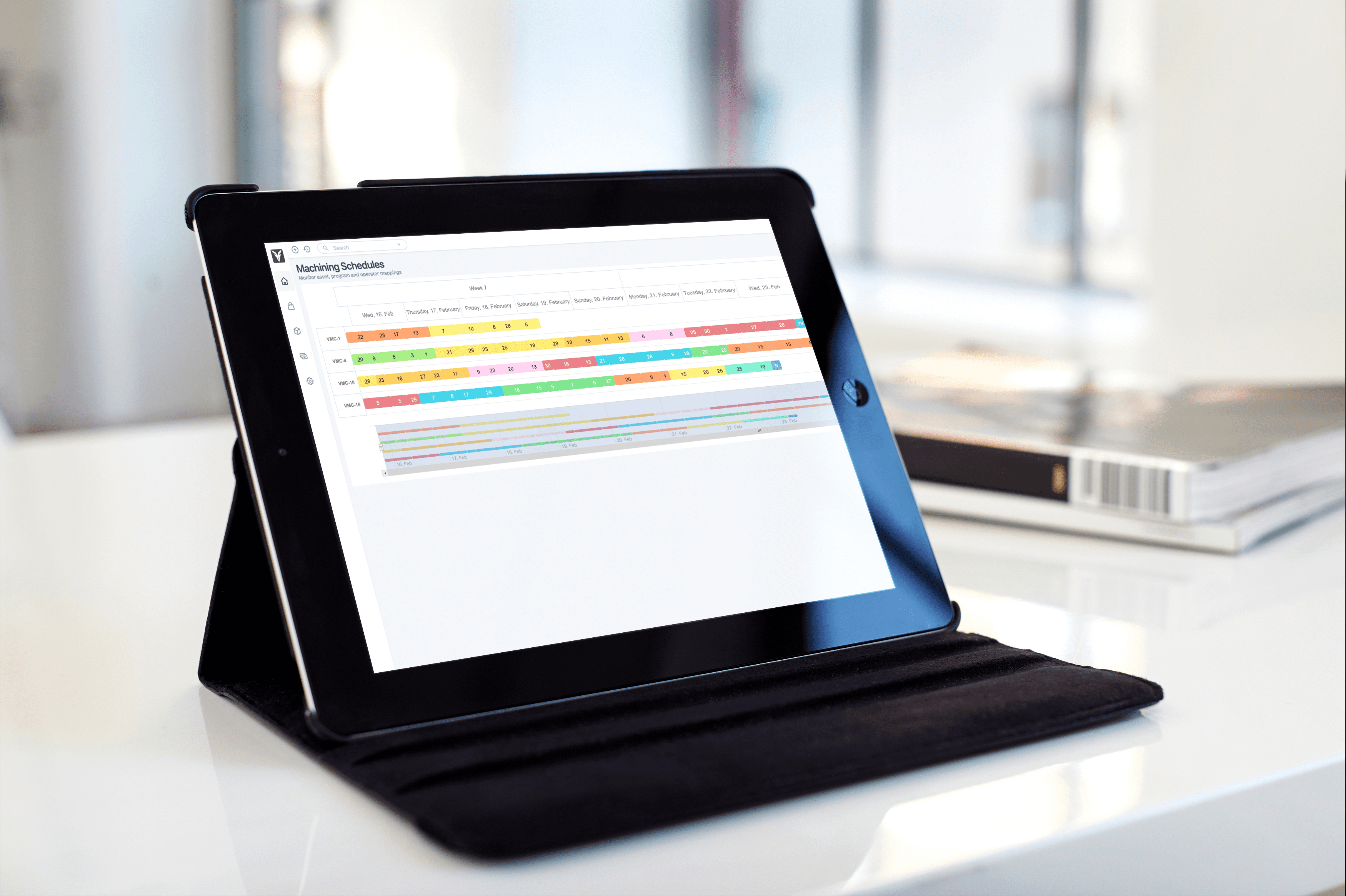

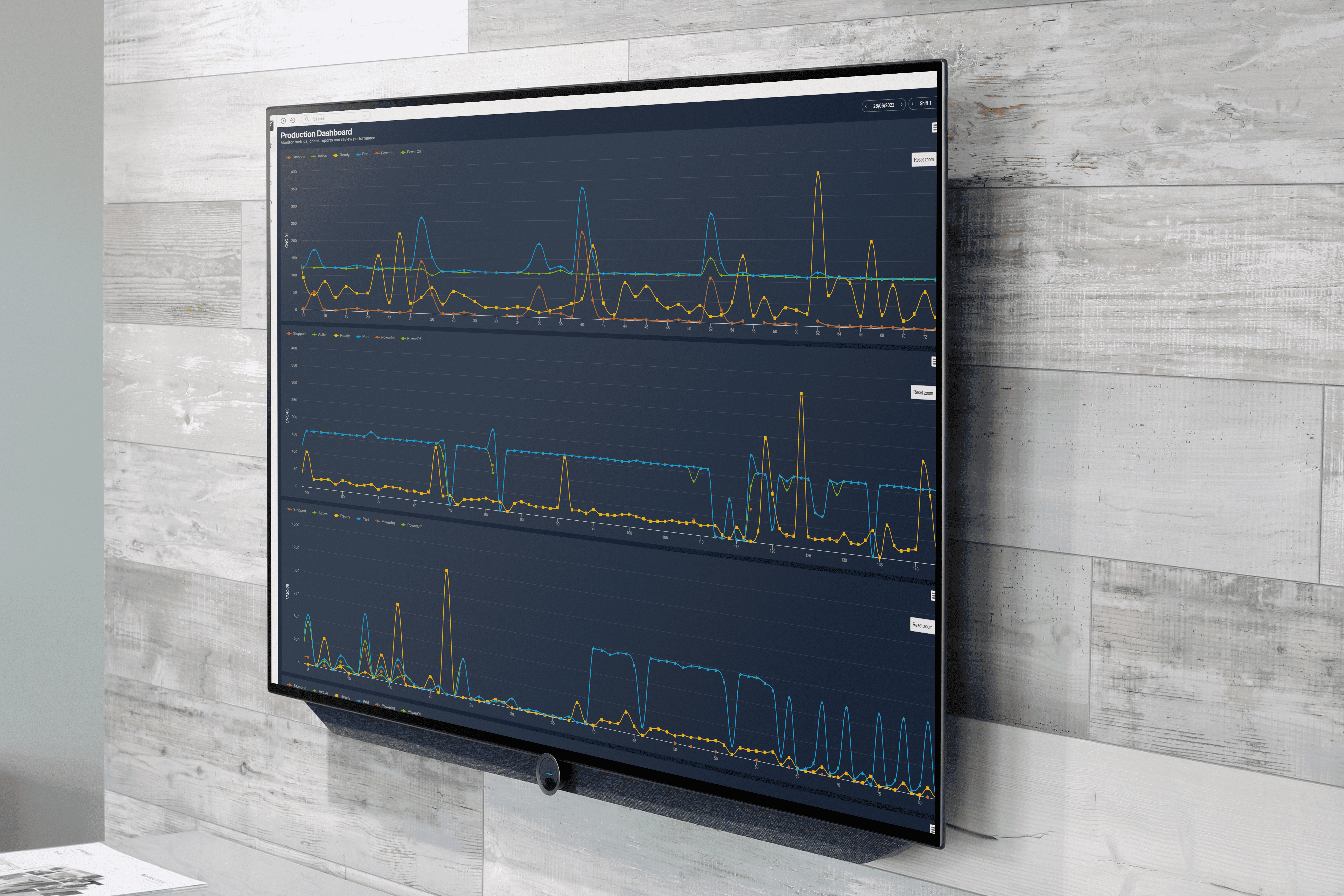

Free Platform for Real-Time Monitoring

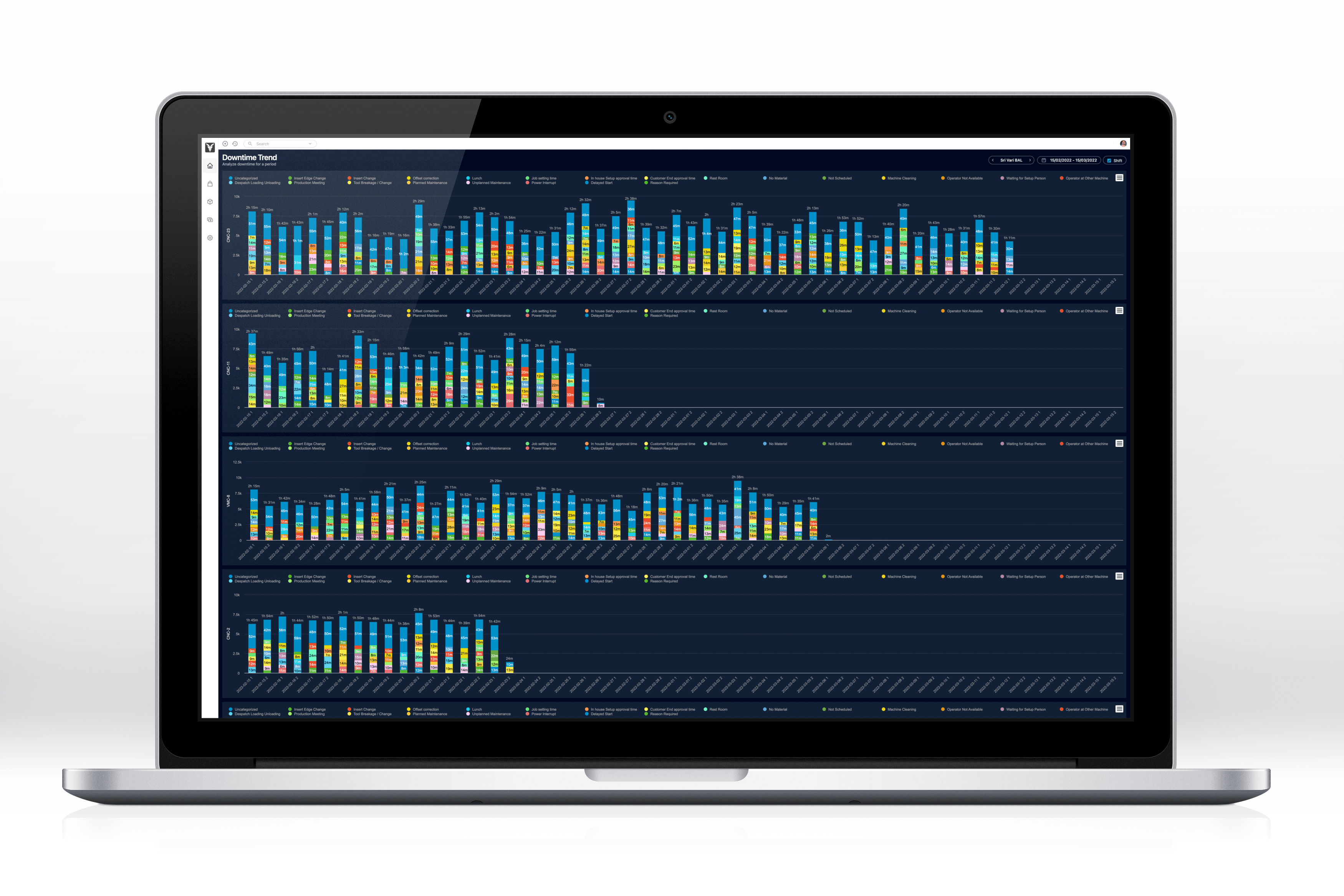

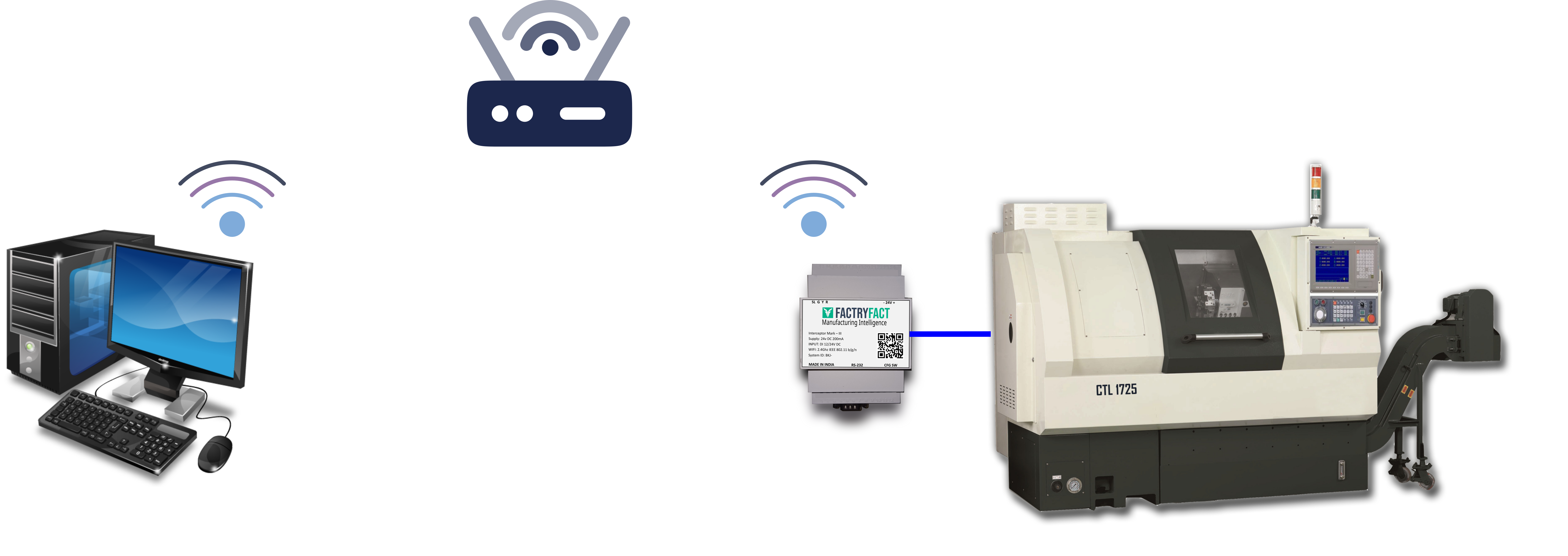

FactryFact M2 is a free production monitoring platform designed for the machining industry. Gain real-time visibility into machine states, value streams, and shop floor operations. Identify downtime, detect bottlenecks, and take action to boost efficiency. Built to empower machining shops with actionable insights that drive results.